The Luxembourg Centre for Logistics and Supply Chain Management (LCL) hosted its recent roundtable event on metal additive manufacturing (AM) on November 13, 2019.

Metal Additive Manufacturing: How do supply chains change when it becomes real?

Moderator: Prof. Anne Lange, University of Luxembourg

Expert: Arvid Eirich, Director Finance, Sales and Technology, Mobility goes Additive e.V., Berlin

Additive Manufacturing is usually used as a synonym to the term 3D printing and refers to manufacturing technologies where material is added layer by layer. As technology allows to additively manufacture components made out of various metals, it becomes ever more attractive to include these components into industrial products. As of now, post-processing of metal AM components still requires significant manual labor and time before a component is ready for use.

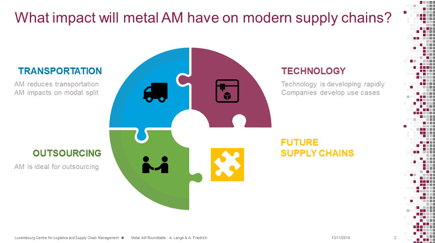

The metal AM roundtable united representatives of 3D printing service bureaus, material providers, software developers, technology users and researchers for knowledge exchange and discussion. Arvid Eirich, Mobility goes Additive e.V., was the expert speaker of the event. His enlightening presentation included the bright and shiny side of additive manufacturing. He commented on an expected annual growth of additive manufacturing by 2030 of 20% and included use cases of metal additive manufacturing. One such example was that of a buffel box, a rarely ever used spare part for rail equipment, that is not carried in spare part inventory. A conventionally manufactured build-to-order unit can easily have a lead time of 12 months, during which the train cannot be used. Being confronted with such a demand, Deutsche Bahn has made use of wire arc additive manufacturing to first print near-shape and then machine the part to its final shape by conventional subtractive manufacturing. Including exhaustive testing of the additively manufactured part, the train was operational again after only two months. Great potential of additive manufacturing lies in specific design for AM. The technology allows for printing structures that cannot be created by alternative manufacturing technology. Stronger and lighter designs are enabled by AM. This, in turn, allows decreasing the weight of, for example, aircraft and cars. What is more, an AM component may comprise several traditional parts that would need to be joined manually. Thus, AM oftentimes simplifies manufacturing processes.

But Arvid was not shy to also talk about company cases who have invested in 3D printers, did not succeed in obtaining the envisioned results and have redrawn from the technology for good. Arvid made a strong point that he advises companies to start investigating additive manufacturing before the market overcomes them. To do so, he suggested teaming up with peers and to start with simple components to gain experience. The experts around the table agreed that every single printing technology, even every single printer type, as well as every printing application requires special knowledge on how to obtain reliable, high quality and reproducible printing results. Discussion further addressed the environmental aspects in additive manufacturing: When powder material is used in the printing process, powder waste will remain. While it may be reused, the 3D printing quality will degrade when printing from waste powder.

Furthermore, Prof. Anne Lange, University of Luxembourg, and Anne Friedrich, TU Darmstadt, presented initial findings from an interview study with companies active in additive manufacturing. They shared that companies take different decisions in how to approach additive manufacturing. The two researchers focused on the organizational aspect, that is, doing AM in-house or outsourcing the printing to 3D printing service bureaus. Among others, the study revealed that in particular large companies with a strong manufacturing expertise prefer to develop their own AM skills whereas smaller players redraw to partnerships with experts. Results of the study are expected for early 2020 and the LCL will be happy to provide more insights.

The event concluded with a lively discussion among the participants.

Thank you to Eurometal for its active participation and its great summary!

The Digital Supply Chain Roundtable Series provides a place where our supply chain community can regularly come together to hear about new discoveries, techniques and ideas.

Supply chain professionals and University of Luxembourg faculty address issues and topics relevant to the industry and leading professionals. They also expose practitioners to industry research conducted at the University and elsewhere. The key aim of the series is to allow its participants to collaborate, sharing business ideas and skill sets to strengthen their businesses together.