The 4th session of the Digital Supply Chain Roundtable Series, on the topic “3D printing: Just an additional manufacturing method or a supply chain disruptor?”, was held at the Luxembourg Centre for Logistics and Supply Chain Management (LCL) on 21 November 2018.

Participants came from industry and academia to discuss different application of 3D printing and how they affect supply chain decisions in current supply chains and how it may affect the shape and design of supply chains in the future. Prof. Rob Basten from Eindhoven University of Technology was a special guest to weigh in on these discussions. In the past few years, he has successfully ran a pilot with the Netherlands army to use 3D printing of spare parts during missions at remote locations.

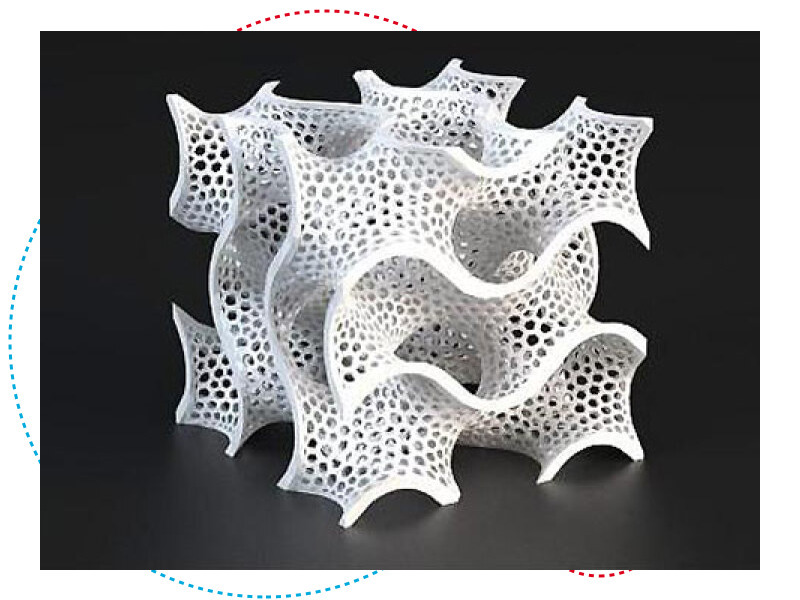

Additive manufacturing has seen successful applications over the past decade in Healthcare (e.g. prosthetic limbs), aerospace (lightweight parts), maintenance repair and overhaul (remote printing of spare parts), and even fashionable consumer products. The success of these applications is based on different features of this technology that impact markets and supply chains to these markets in different ways.

- In maintenance repair and overhaul, success is based on the ability to print in remote locations and to maintain manufacturing capability without the need to storing molds and other specialized equipment.

- In aerospace, success is based on the ability to significantly reduce the weight of parts. Weight drives fuel consumption of aircraft and fuel consumption is a major cost driver for airlines.

- In healthcare, success is based on the ability to customize designs to specific patients.

Other drivers of success include less waste of raw materials, reduced cycle times if design is included and simplified custom clearance procedures.

Participants of the roundtable concluded that all these successful examples remain niche markets. The economies to use additive manufacturing are not yet viable for the bulk of goods. However, 3D printing is not only a manufacturing technology, but also a new design technology. It is possible and perhaps likely that this technology will enable to design of goods for which there is a large global market, but that can only be manufactured by 3D printing. If this happens, a supply chain disruption is likely to follow.

Supply chain managers and firms will have to grapple with questions such as:

- Will 3D printing replace transport as the major activity of 3PLs?

- When should a firm start investing in this new technology and developing their own capability?

- How do you manage a hybrid supply chain with both additive and traditional manufacturing assets?

These questions remain poignant for the time being.